This product is specially developed based on the high rainfall and humid construction environment in the south. It is a high-performance epoxy structure repair mortar with oil and water affinity. This epoxy structure repair mortar has the advantages of high bonding strength, curing in water and wet surfaces, small shrinkage during the hardening process, high temperature resistance, high durability, high weather resistance, no volatile solvents, non-toxic and environmentally friendly, and convenient construction.

一、Product Introduction

This product is specially developed based on the high rainfall and humid construction environment in the south. It is a high-performance epoxy structure repair mortar with oil and water affinity. This epoxy structure repair mortar has the advantages of high bonding strength, curing in water and wet surfaces, small shrinkage during the hardening process, high temperature resistance, high durability, high weather resistance, no volatile solvents, non-toxic and environmentally friendly, and convenient construction.

二、Main characteristics

Good adhesion performance, high adhesion strength, and good affinity with various substrates;

Convenient construction, can be carried out under high and low temperature conditions as well as in dry and humid environments, saving labor and time, and having low overall costs;

Corrosion resistance, high temperature resistance, low temperature resistance, and aging resistance;

Non deteriorating, earthquake resistant, non-toxic and harmless, odorless, and non polluting to the environment;

Stable quality and excellent performance.

三、Technical Parameter

|

Basic performance item |

Performance requirement |

Experimental result |

||

|

Colloidal property |

Initial set/min |

|

≥60 |

|

|

|

Final set/h |

|

≤3 |

|

|

|

Splitting tensile strength/MPa |

≥7 |

9 |

|

|

|

Flexural strength/MPa |

≥12 |

13 |

|

|

|

Compressive strength |

7d |

≥30 |

≥40 |

|

|

|

28d |

≥55 |

≥60 |

|

Bonding power |

Shear strength bonded to steel wire rope /MPa |

Standard value |

≥9 |

9.5 |

|

|

|

Mean value |

≥11.5 |

12 |

|

|

Positive pull with concrete Bond strength /MPa |

≥2.5, and it is concrete Cohesive failure |

≥2.5, and it is concrete Cohesive failure |

|

四、Application scope

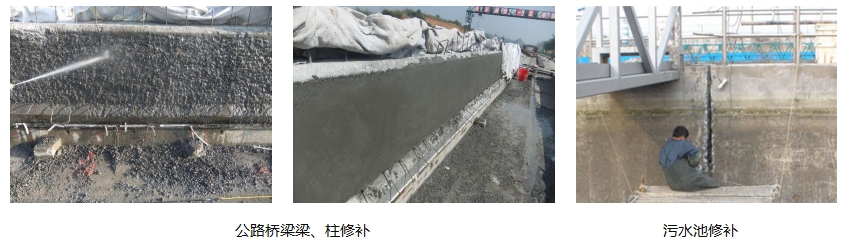

Applied in reinforcement projects such as grouting and grouting in structural repair engineering;

Repair and base treatment of airport runways, highways, tunnels, and bridge openings;

The repair and leakage repair of basements and civil air defense projects in industrial and civil buildings;

Waterproof and anti-seepage measures for various types of water pools, swimming pools, and sewage tanks, as well as for grain warehouses, household bathrooms, kitchens, factories, and enclosed balconies.

五、Product appearance

This product is composed of three components: A, B, and C. Component A is a light yellow or colorless transparent gel like substance, component C is a colorless light yellow thixotropic paste like substance, and component C is a powder reinforced filler. After mixing the three components, it is cement colored, and after curing, it matches the color of cement mortar;

The actual mixing ratio of each component is A: B: water: C=20:10: (10-20): (50-100)

六、Usage

During construction, add component B to component A and mix evenly with machinery;

Add water of equivalent mass to component B, add component C, and continue stirring thoroughly until component C is completely dissolved;

The entire structural adhesive has a uniform color, no clumped particles, and can be used without layering after standing. It can be adjusted and used as needed;

Usage: Same as the usage method of ordinary mortar.

七、Precautions and Applications

Before use, observe whether components A and B have uniform color and no obvious impurities, and whether component C does not clump; The use should be stopped if it is inconsistent with the above phenomenon;

Component B should be added to component A and stirred, and component A should not be added to component B and stirred. A. After stirring component B evenly, the addition of component C should be thoroughly stirred;

If layering occurs after standing, stir thoroughly before use. If layering still occurs after mixing, the use should be stopped and the technical department of our company should be contacted;

A small amount of gel should be taken for observation after each mixing. Observe whether there is any abnormal phenomenon (explosion) after standing still. If there is any abnormality, the use should be stopped immediately and the technical department of our company should be contacted;

The amount of glue mixed at once should not be too much, and it should be ensured that the mixed glue can be used up within 1.5 hours;

During construction, the base layer should be cleaned to keep it flat, clean, and free of dirt; Clean with effective solvents in a timely manner after construction is completed;

Under normal storage conditions, the storage period is 90 days. If it exceeds 90 days, it must be verified through testing before use.

This product refers to the "Technical Specification for Safety Appraisal of Engineering Structural Reinforcement Materials" GB50728-2012 standard

Home

Home

Case

Case

News

News

Tel

Tel