RJ-HPSC high-performance shotcrete is a new material for shotcrete construction that has been jointly developed by Renjian Baogu Technology Center, Central South University, Changsha University of Science and Technology, Hunan Vocational and Technical College of Transportation, Hunan Tengda Geotechnical Engineering Technology Co., Ltd., and other institutions through years of hard work. The technology consists of a complete set of techniques such as high-performance shotcrete materials, shotcrete construction processes, and shotcrete equipment. Mainly used in non excavation construction, repair, reinforcement, waterproofing, anti-corrosion, etc. for highways, high-speed railways, bridges, tunnels, airports, ports, dams, building structures, urban underground sewage and drainage pipelines. Especially in situations where the project schedule is tight, material requirements are high, the working face is complex, and construction conditions are difficult, using HPSC spray construction can achieve good results and solve the technical problem of high-performance concrete that cannot be sprayed for many years.

一、Product Introduction

RJ-HPSC high-performance shotcrete is a new material for shotcrete construction that has been jointly developed by Renjian Baogu Technology Center, Central South University, Changsha University of Science and Technology, Hunan Vocational and Technical College of Transportation, Hunan Tengda Geotechnical Engineering Technology Co., Ltd., and other institutions through years of hard work. The technology consists of a complete set of techniques such as high-performance shotcrete materials, shotcrete construction processes, and shotcrete equipment. Mainly used in non excavation construction, repair, reinforcement, waterproofing, anti-corrosion, etc. for highways, high-speed railways, bridges, tunnels, airports, ports, dams, building structures, urban underground sewage and drainage pipelines. Especially in situations where the project schedule is tight, material requirements are high, the working face is complex, and construction conditions are difficult, using HPSC spray construction can achieve good results and solve the technical problem of high-performance concrete that cannot be sprayed for many years.

The main technical parameters of the sprayed concrete are: 28 day compressive strength ≥ 80MP, flexural strength ≥ 6MPa, and bond strength ≥ 1.2MPa. After hardening, it has excellent properties such as waterproofing, anti-corrosion, wear resistance, drag reduction, high strength, durability, and environmental protection, and has multiple patents and completely independent intellectual property rights.

二、Characteristics and Technical Parameters of RJ-HPSC Series

HPSC high-performance shotcrete has good shotcrete thixotropy, excellent shotcrete construction performance, and strong adhesion with the base layer;

The thickness of the dome spraying can reach 100mm, and the rebound rate of the spraying construction is less than 5%. After spraying, there is a certain amount of time for finishing operation;

High early strength, 24-hour compressive strength ≥ 25MPa, 28d ≥ 80MPa;

Good adhesion, 28 days ≥ 1.2MPa;

Micro expansion ensures that the repaired area does not shrink, ensuring that there are no gaps or looseness in the bonding area, and that it is firmly bonded to the old concrete. Wide adaptability, non-toxic and harmless, environmentally friendly products;

Good durability, waterproof, anti-corrosion, anti-seepage, water increasing, and drag reducing. No rust on steel components, durable and sturdy;

Good impact resistance, suitable for special structures that require high load-bearing capacity.

|

item |

Performance index |

|||

|

|

40 |

60 |

80 |

|

|

Setting time (min) |

Initial set |

≥45 |

≥45 |

≥45 |

|

|

Final set |

≤600 |

≤600 |

≤600 |

|

Compressive strength (MPa) |

24h |

≥10 |

≥15 |

≥25 |

|

|

3d |

≥20 |

≥40 |

≥50 |

|

|

28d |

≥40 |

≥60 |

≥80 |

|

Flexural strength (MPa) |

28d |

≥4 |

≥5 |

≥6 |

|

Bond strength (MPa) |

28d |

≥1.2 |

≥1.2 |

≥1.2 |

|

impermeability |

28d |

P6 |

P8 |

P10 |

三、Application scope

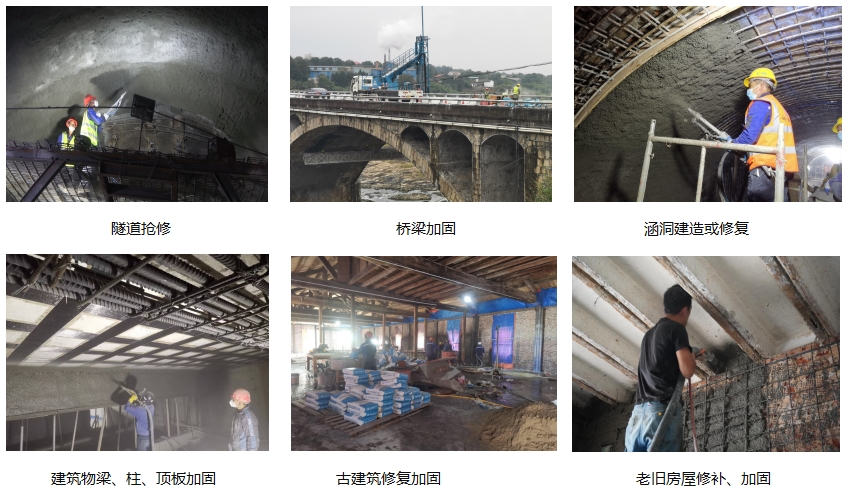

The outer protective layer used for building steel structures can significantly improve the service life of components;

Used for permanent support construction in tunnel construction;

Used for the maintenance and reinforcement of buildings, bridges, and tunnels, as well as the repair of damaged parts;

Used for reinforcing the walls of old houses, thickening and widening the walls;

Structural maintenance and reinforcement of buildings, bridges, tunnels, and docks.

四、Usage

Surface treatment: Clean the foundation surface and ensure that there are no debris such as crushed stones, floating slurry, dust, oil stains, and release agents. Spray interface agent on the foundation surface before construction;

Construction method: HPSC premix has good thixotropic properties and can be manually applied or mechanically sprayed for construction;

Slurry preparation: Add clean water in a clean container at a ratio of 100:12-16, and stir with a forced mixer until the slurry is evenly mixed. Do not prepare too much material at once, and use it up within 45 minutes;

Construction: Connect the spray conveying hose to the spray gun, adjust the pressure of the spray machine and air compressor, start the spray machine, adjust the air pressure, and spray the slurry from the spray gun mouth in a mist form. After the spray slurry is formed, uneven areas can be manually smoothed and smoothed;

Maintenance: After initial setting, spray water to moisturize and maintain. Special curing agents can also be sprayed or covered with film for curing;

Under normal storage conditions, the storage period is 90 days. If it exceeds 90 days, it must be verified through testing before use.

五、Typical applications

This product is based on the Technical Specification for Application of High Performance Shocked Concrete T/HCBA 002-2022 standard

Home

Home

Case

Case

News

News

Tel

Tel